I. The Logic and Core Significance of Recycled Fabrics

Against the backdrop of increasingly severe global resource constraints and environmental challenges, the textile industry's long-standing reliance on virgin resources and high pollution emissions is becoming unsustainable. Recycled fabrics have emerged as a key breakthrough in the industry's green transformation.

The core of recycled fabrics lies in the recycling of waste. Traditional textile production consumes vast quantities of resources like petroleum and cotton. Recycled fabrics, on the other hand, incorporate recycled materials like discarded textiles and plastic bottles back into the production process, transforming "waste" into reusable textile raw materials. For example, in the case of plastic bottle recycling, these seemingly useless waste materials can be transformed into polyester fibers through processes such as shredding, cleaning, and melt spinning, which can then be woven into various fabrics, significantly reducing reliance on virgin resources.

From an environmental perspective, recycled fabric production offers significant advantages in terms of energy consumption and emissions. The energy required to produce recycled polyester fabrics is far lower than that of virgin polyester, and emissions of pollutants such as carbon dioxide are also significantly reduced. This has significant implications for mitigating global climate change and promoting the development of a low-carbon economy. It also reduces land occupation and air pollution caused by waste landfill and incineration, contributing to the development of a circular ecosystem.

II. Technological Evolution and Expanded Applications of Recycled Fabrics

The production of recycled fabrics involves the coordinated development of multiple technologies. For example, in the production of recycled polyester fabrics, recycled polyester bottles are first carefully sorted and thoroughly cleaned to thoroughly remove impurities and contaminants. Subsequently, they are crushed to produce polyester flakes, which are then melted and spun into fibers suitable for textiles. During this process, ensuring the consistent quality of the recycled material and improving fiber performance are key technical challenges.

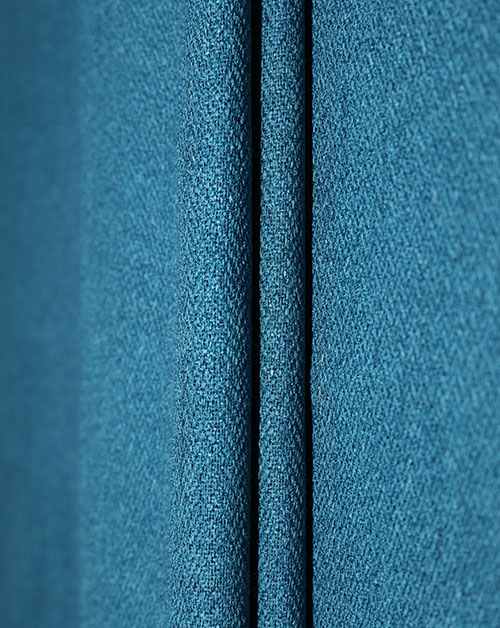

In recent years, technological innovation has enabled a significant leap in the performance of recycled fabrics. Previously, recycled fabrics lagged behind virgin fabrics in terms of feel and durability. However, today, thanks to advanced spinning technologies and the addition of functional additives, recycled fabrics not only rival virgin fabrics in appearance and feel, but also surpass them in functional properties like breathability and wrinkle resistance.

In terms of application scenarios, the reach of recycled fabrics continues to expand. Initially used primarily in outdoor products and home textiles, it has now penetrated deeply into the fashion apparel industry. Many well-known clothing brands have launched recycled fabric product lines, responding to consumer demand for green and environmentally friendly products while also cultivating a sustainable image for their brands and further promoting the mass market adoption of recycled fabrics.

III. Future Development Trends of Recycled Fabrics

With growing environmental awareness, consumer demand for green products is expected to explode, providing a continuous driving force for the recycled fabric market. Simultaneously, policy support is being continuously strengthened, with the introduction of a series of policies and regulations supporting the circular economy, creating a favorable development environment for the recycled fabric industry and further promoting standardization and large-scale development.

Technological innovation will be the core driving force behind the continued development of the recycled fabric industry. In the future, more efficient recycling technologies and production processes are expected to emerge, further improving the quality of recycled fabrics and reducing production costs. For example, in the recycling process, smarter sorting technologies may be introduced to increase the purity of recycled materials. In the production process, new spinning technologies may enable recycled fibers to achieve performance that approaches or even exceeds that of virgin fibers.

Recycled fabrics are not only a key achievement in the textile industry's green transformation but also a mainstream direction for future industry development. Driven by technological progress, market demand and policy support, recycled fabrics will occupy an increasingly important position in the textile market, leading the entire industry towards a greener, more environmentally friendly and innovative direction, and contributing the textile industry's strength to global sustainable development.

English

English 中文简体

中文简体 русский

русский عربى

عربى