As the concept of sustainable development rapidly gains popularity globally, recycled fabrics have gradually become a focus of attention in the textile industry. They not only represent a positive response to environmental protection, but also represent the intersection of emerging materials technologies, the fashion industry, and the circular economy. As the concept of green consumption continues to gain traction globally, recycled fabrics are demonstrating unprecedented market potential and technological breakthroughs.

The Essence of Recycled Fabrics: Transforming Waste into New Value

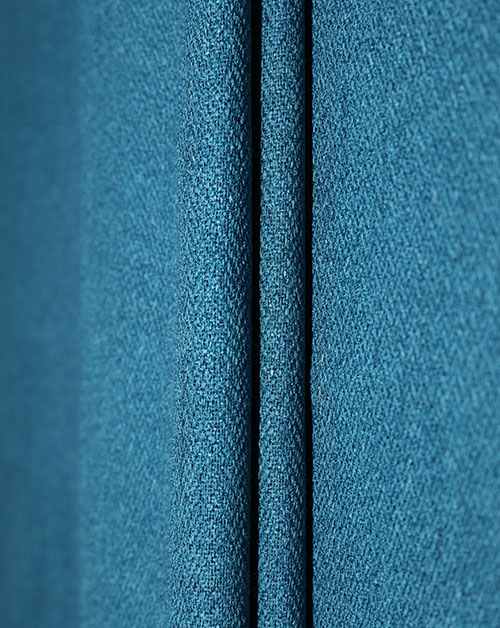

Recycled fabrics are made by recycling waste textiles, plastic bottles, fishing nets, and industrial scraps through a series of reprocessing processes, including cleaning, crushing, melting, spinning, and weaving. Their core purpose lies not only in "material reuse" but also in giving waste a second life through technological means, thereby achieving energy conservation, emission reduction, and pollution reduction.

Currently, mainstream recycled fiber raw materials include recycled polyester (rPET), recycled nylon (rNylon), recycled cotton, and recycled wool. Recycled polyester is widely used due to its wide availability, stable performance, and manageable production costs. Recycled nylon, due to its excellent strength and abrasion resistance, is widely used in high-performance applications such as sports fabrics, swimwear, and outdoor gear. Natural regenerated fibers, such as recycled cotton and recycled wool, face challenges such as a high proportion of short fibers and inconsistent quality. However, with the development of blending technology and chemical recycling processes, their quality has become increasingly stable.

High Performance and Sustainability Go Hand in Hand: Technological Innovation Drives the Upgrade of Recycled Fabrics

The value of modern recycled fabrics goes beyond eco-friendly labels. An increasing number of companies and research institutions are leveraging technological innovation to further evolve fabric performance. From physical and chemical recycling technologies at the fiber source to low-carbon and energy-saving improvements in the spinning and weaving processes, every step creates opportunities for improved performance in recycled fabrics.

The rise of chemical recycling technology is particularly crucial. It can reduce waste polyester to its monomeric level and then repolymerize it to produce high-quality recycled polyester with properties nearly identical to virgin polyester. This process effectively addresses the impurity issues and mechanical property degradation associated with physical recycling, significantly expanding the application scope of recycled fibers. During the weaving process, the incorporation of emerging technologies such as 3D weaving and smart knitting has enabled recycled fabrics to possess greater flexibility, fit, and functionality, meeting diverse needs across sports, outdoor, medical, and home applications.

The Future Standard for Eco-Friendly Fashion: The Rapid Penetration of Recycled Fabrics into the Apparel Industry

The apparel industry is a major global consumer of resources and pollutants. However, as sustainability issues become increasingly prominent, more and more brands are incorporating environmental protection into their core strategies. Driven by this trend, recycled fabrics are becoming a staple material for many fashion and sportswear brands. From high street fast fashion to luxury brands and functional sportswear, recycled fabrics are gaining popularity due to their sustainable labeling and continuously improving quality standards.

With the global goal of "net zero carbon," recycled fabrics are no longer just an environmental slogan; they have become a key enabler for the textile industry's transformation and upgrading, and for brands to build sustainable value. From source design to end consumption, recycled fabrics are driving the restructuring and green transformation of the entire industry chain. In the near future, recycled fabrics will not only appear in niche products touted as environmentally friendly, but will be fully integrated into daily consumption, industrial manufacturing, and social responsibility systems. It represents not only an environmentally friendly material, but also a manifestation of responsibility, an extension of innovation, and a future-oriented lifestyle.

English

English 中文简体

中文简体 русский

русский عربى

عربى