In the field of modern textiles, Cut Pile Fabric is widely used in clothing, home furnishings, automotive interiors and other fields due to its soft touch, elegant appearance and excellent performance. As consumers' requirements for fabric comfort and aesthetics increase, Cut Pile Fabric is gradually becoming the focus of market attention.

What is Cut Pile Fabric? — Structural principle of cut pile fabric

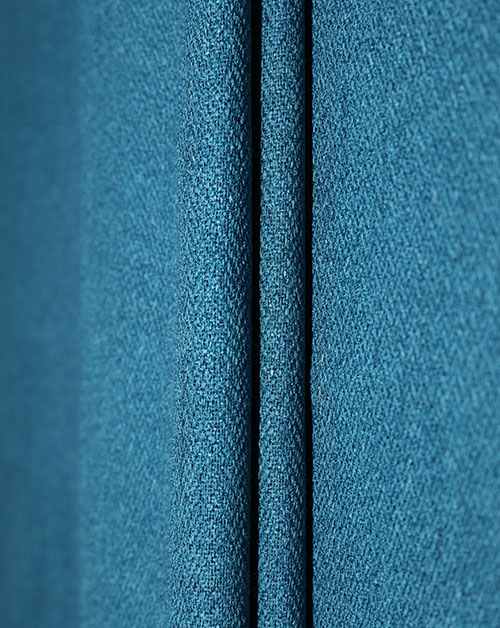

Cut Pile Fabric is a fabric with a cut pile structure on the surface. Its structure comes from the fact that after the yarn is formed into a loop during the weaving process, the looped yarn is cut by mechanical means to form a pile surface with uniform pile and full three-dimensional pile. Unlike Loop Pile (loop pile fabric), the free ends of the pile of Cut Pile can better reflect light, bringing a softer and more high-end visual effect.

Commonly used basic fibers for this type of fabric are:

Polyester: strong wear resistance, affordable price;

Cotton: natural and environmentally friendly, good breathability;

Nylon: excellent elasticity, suitable for high-performance fabrics;

Viscose: smooth feel, easy to dye.

Process analysis: manufacturing process of cut pile fabric

The production process of Cut Pile Fabric is relatively complex, usually including the following main steps:

Basic weaving: using double or multi-layer looms, the warp and weft are interwoven to form a fabric with a potential cut pile structure;

Pile treatment: the loop pile on the surface of the fabric is cut off by a special cut pile machine to form a neat and consistent pile;

Brushing and shaping: further improve the softness of the pile surface and improve the consistency of the pile direction;

Dyeing and finishing: dyeing, anti-wrinkle, anti-static and other post-treatment processes are carried out according to the application requirements.

The height, density and directionality of the cut pile will directly affect the appearance and feel of the fabric, so this link has extremely high requirements for equipment and technical level.

Material and performance: Why is cut pile fabric so popular?

The reason why Cut Pile Fabric is widely used is due to its superior comprehensive performance:

Soft and warm to the touch: suitable for close-fitting wear and winter warming products;

Natural luster and rich colors: highly decorative and visually beautiful;

Strong sound absorption and heat preservation: widely used in curtains, carpets, car interiors and other scenes;

Both elasticity and wear resistance: long service life and low maintenance cost.

Functional finishing can be added to cut pile fabrics in the post-processing stage, such as fireproofing, antibacterial, waterproofing, etc., to meet the needs of special industries.

Wide range of applications: comprehensive penetration from clothing to home

Clothing field: Cut Pile Fabric is particularly common in winter clothing, such as velvet coats, suede base shirts, thermal pants, etc., because of its thermal insulation and fashion sense;

Home decoration: It is widely used in sofa fabrics, curtains, cushions and bedding to create a warm and comfortable living atmosphere;

Carpets and pads: Cut pile carpets are soft and have outstanding sound absorption, making them the first choice for high-end hotels and families;

Automotive interiors: The roof and seat covering materials use cut pile structure to improve the overall grade and ride comfort.

Cut pile fabric (Cut Pile Fabric) is at the forefront of innovation in the textile industry. Its diverse structural performance and continuously upgraded functional properties make it occupy an irreplaceable position in the modern fabric system. With the continuous optimization of production processes and the continuous evolution of consumer aesthetics, the market potential of Cut Pile Fabric will continue to be released.

English

English 中文简体

中文简体 русский

русский عربى

عربى