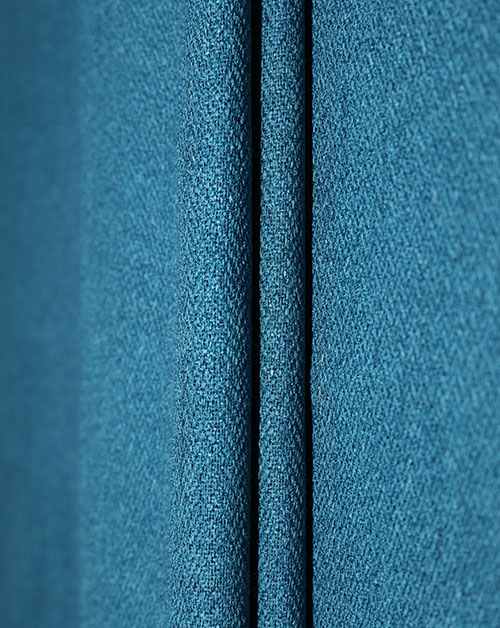

Pile fabric is woven with one or more yarns that are sheared to create tufts of fibers that stand up from the underlying foundation texture. The shearing process is either done by hand or on a high-speed loom that uses knives to cut the yarns. Both methods produce a fabric that has different textural properties. Generally, the fabric is made from high-quality wool or other natural fibers such as cotton and linen. The type of weave can also influence the feel and appearance.

The way that a fabric is woven will determine whether the yarns are sheared in a “cut pile” or an uncut pile construction. A cut pile fabric has yarns that are sheared as they are pulled from the loom to form tufts of fibers that stand up in a dense, continuous row. Alternatively, the yarns may be sheared before they are woven to make an uncut pile fabric. Uncut pile fabrics are more durable than cut-pile fabrics and often have a longer life cycle.

Choosing which way to run the pile is an important consideration when sewing pile fabric. Running the pile upward results in a smoother, more luxurious finish, while running it downward produces a fabric that has a rougher feel. The final choice depends on the end use. If durability is a major factor, then it is to run the fabric with the pile down.

There are several types of weaves that can be used to produce a cut-pile fabric, including warp and weft pile. In warp-pile weaves, the weft threads are sheared to produce tufts of fibers that stand up as the fabric is woven. During the weaving process, the warp and weft yarns are tied together with a special yarn called a kokane or jinako (knitted chenille) to produce the fabric.

In weft-pile weaves, the yarns are sheared as they are inserted into the weft to form tufts. The yarns can then be twisted to form the desired fabric. A weft-pile fabric can be woven as a single cloth or by double weaving. The common method is to weave two normal fabrics in face-to-face with a special warp yarn that links the two pieces together. This produces a tufted fabric called mohair pile plush or frieze. It is also possible to produce a cut-pile fabric from a knitted fabric by using the same technique.

English

English 中文简体

中文简体 русский

русский عربى

عربى