In the modern textile industry, Brushing Fabric has become a highly sought-after material due to its unique tactile and visual effects. Whether in clothing, home textiles, or high-end interior decoration, brushed fabrics offer a distinctive textural experience.

Material Characteristics of Brushing Fabric

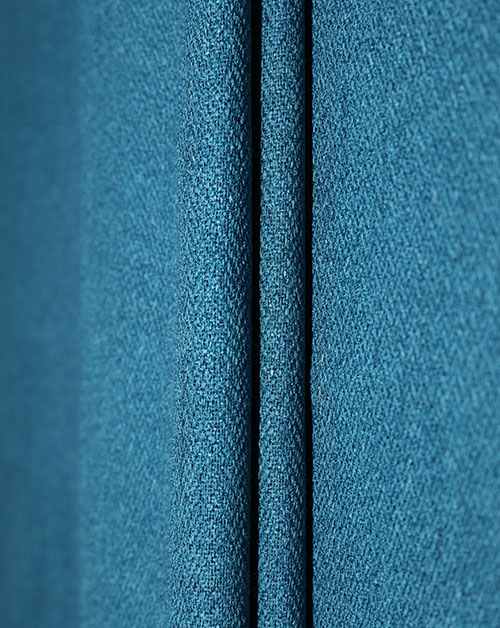

Brushing Fabric, or fabric treated with a brushing process, derives its core appeal from its soft, fluffy surface texture. After brushing, a short, even layer of fluff is formed on the fiber surface, which not only enhances the fabric's feel but also gives it a visually warm appearance. The type of fiber significantly impacts the texture of Brushing Fabric. Natural fibers such as cotton and wool, after brushing, have a delicate feel and excellent warmth retention, while synthetic fibers such as polyester, after brushing, are more elastic and wrinkle-resistant.

The micro-structure of the brushed fabric's surface determines its moisture absorption and breathability. The short, dense layer of fluff increases moisture absorption while retaining the fabric's original breathability, making garments more comfortable against the skin. The soft sheen that brushed fabrics exhibit under light gives them a more layered and sophisticated visual appeal.

Analysis of Brushing Fabric Production Process

The uniqueness of Brushing Fabric mainly stems from its production process. Traditional brushing involves using specialized mechanical equipment to raise the fibers on the fabric surface, causing them to become slightly fluffy and evenly arranged. The entire process requires strict control over fiber selection, fabric density, and brushing intensity.

In the process, the raw fabric is first pre-treated to ensure fiber flatness, and then enters the brushing machine. The brushing machine uses roller brushes or needle combs to evenly raise the fibers on the surface, forming a soft layer of fluff. Different brushing parameters directly affect the fabric's feel, fluff density, and durability. High-density brushing increases the fabric's warmth and fluffiness, while light brushing emphasizes softness and drape.

After brushing, the fabric usually undergoes shaping and finishing processes to ensure that the fluff layer is neat, durable, and resistant to shedding. Surface finishing can also enhance the pilling resistance of the fabric, allowing Brushing Fabric to maintain a good appearance and feel during use.

Functional Applications of Brushing Fabric

Brushing Fabric has a wide range of applications, and its functional characteristics show unique advantages in different fields. In the apparel industry, brushed fabrics, with their comfortable and soft texture, are the preferred material for autumn and winter clothing, especially for products requiring close contact with the skin or high warmth, such as underwear, loungewear, and outerwear. Its fluffy fiber structure not only enhances warmth but also improves the fit, making the clothing more comfortable and natural.

In home textile products, Brushing Fabric is widely popular for its soft feel and delicate touch. Bedding, blankets, cushions, and other products treated with the brushing process exhibit a warm and high-quality feel, meeting consumers' dual needs for comfort and aesthetics.

Brushing fabric also shows unique advantages in functional products. Its fine surface fluff layer can improve the thermal insulation performance of the fabric, and through reasonable fiber selection and post-processing, the fabric can be given functions such as anti-static, antibacterial, or easy cleaning, meeting the needs of specific usage environments.

Maintenance and Care of Brushing Fabric

Although Brushing Fabric has good durability and comfort, its delicate fluff structure requires scientific maintenance methods. During washing, high temperatures and strong friction should be avoided to prevent fiber damage or shedding of the fluff layer. It is generally recommended to wash gently with warm water and a neutral detergent, avoiding prolonged soaking and strong mechanical agitation.

During drying, high-temperature drying should be avoided as much as possible; natural drying or low-temperature air drying should be chosen to maintain the fluffiness and softness of the fluff layer. During daily storage, care should also be taken to avoid compression or overlapping to prevent damage to the fabric's three-dimensional structure and feel. With proper care, Brushing Fabric products can maintain their soft and comfortable characteristics for a long time and extend their service life.

FAQ (Frequently Asked Questions)

Q1: What fiber materials are suitable for Brushing Fabric?

A1: Brushing Fabric can be applied to natural fibers such as cotton and wool, as well as synthetic fibers such as polyester. Different fibers exhibit different hand feel and performance characteristics after brushing treatment.

Q2: What are the precautions for maintaining brushed fabrics?

A2: When cleaning, avoid high temperatures and strong friction; use warm water and a neutral detergent for gentle cleaning. When drying, avoid high-temperature drying; opt for natural air drying or low-temperature tumble drying.

Q3: What are the main functional advantages of brushed fabric?

A3: Soft touch, good thermal insulation, fluffy visual effect, and the ability to acquire functions such as anti-static, antibacterial, or easy cleaning through post-processing.

Q4: What are the differences in the application of brushed fabric in clothing and home textiles?

A4: In clothing, the focus is on comfortable fit and warmth; in home textiles, the emphasis is on soft touch, fluffiness, and a visually warm effect.

Q5: What are the future development trends of brushed fabric?

A5: With technological improvements and functional expansion, brushed fabric will find more applications in high-end home textiles, sportswear, and smart textiles.

English

English 中文简体

中文简体 русский

русский عربى

عربى