In the modern textile industry, cut pile fabric, with its unique surface texture, comfortable feel, and excellent visual appeal, has become a popular choice in home décor, apparel fabrics, and automotive interiors. This type of fabric undergoes a special finishing process that cuts open the looped yarns on the fabric surface to create a soft pile, giving it a delicate, smooth feel and elegant appearance.

I. Structural Characteristics and Forming Principles of Cut Pile Fabrics

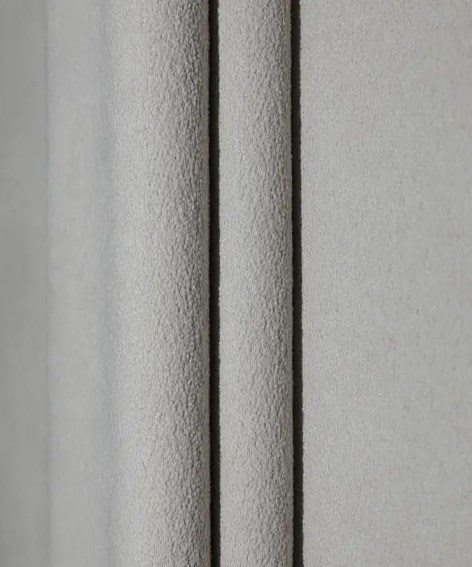

Cut pile fabric is a fabric structure based on looped pile, with the pile surface formed by cutting. During the weaving process, the fabric is originally a looped pile structure; through a subsequent cutting process, the loops are cut open, exposing the fiber ends to the surface and forming a uniform, upright pile layer. This structure not only provides a soft, smooth feel but also enhances the fabric's thickness and warmth.

Cut pile fabrics typically use cotton, polyester, nylon, viscose, or blended fibers as the main raw materials. Depending on the yarn twist, density, and fiber length, they can exhibit a variety of textures, from silky smooth to densely piled. The direction and density of the pile on the fabric surface are key factors determining its quality and application.

II. Production Process and Key Technologies of Cut Pile Fabrics The core of cut pile fabric production lies in the precise control of the cut pile process. It typically employs a double-layer fabric structure, obtaining two symmetrical cut pile fabrics by cutting the middle layer yarn. The entire process includes weaving, dyeing and finishing, shearing, setting, and finishing stages.

In the weaving stage, controlling yarn tension and loop height is crucial for the uniformity of the pile. The shearing process uses high-precision cutters to evenly cut the loops, ensuring consistent pile length and a smooth, delicate surface. The dyeing and finishing stage uses high-temperature, high-pressure dyeing and softening treatments to achieve higher softness and abrasion resistance while maintaining vibrant colors. The setting and finishing processes further enhance the fabric's shape stability and surface luster.

Modern cut pile fabric production is gradually moving towards intelligent and automated processes. Digital control systems can precisely adjust the angle of the shearing cutters and fabric tension, resulting in more stable fabric quality and a smoother hand feel.

III. Performance Advantages and Visual Effects of Cut Pile Fabrics

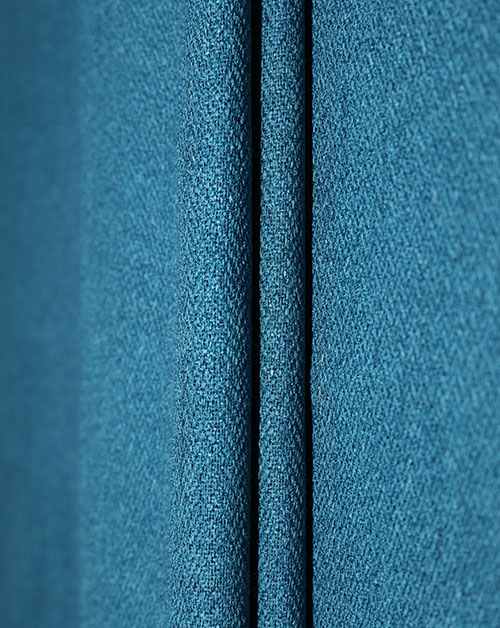

The most prominent characteristics of cut pile fabrics are their soft and comfortable feel and elegant and delicate appearance. Their pile layer reflects and absorbs light, creating natural color variations that give the fabric a rich sense of layering and a noble texture under light. Furthermore, the pile layer structure also provides excellent heat insulation and moisture absorption, making it suitable for autumn and winter clothing and high-end home textiles.

In terms of durability, fabrics woven with high density and precisely sheared pile possess good abrasion resistance and anti-pilling properties, resulting in a long service life. Some synthetic fiber cut pile fabrics also have stain-resistant, fade-resistant, and easy-to-clean properties, further enhancing their practicality.

Cut pile fabrics exhibit unique light and shadow variations. When the pile direction or the angle of light changes, the fabric surface displays varying shades of light, making it more expressive and artistic in interior decoration and clothing design.

IV. Application Trends of Cut Pile Fabrics in Various Industries

As consumers' pursuit of comfort and visual aesthetics continues to increase, the application areas of cut pile fabrics are expanding. In the home textile industry, it is widely used in sofa fabrics, curtains, cushions, carpets, and other products, giving spaces a soft and warm atmosphere. Due to its delicate texture and rich colors, it is often used in high-end interior design to enhance the overall sophistication of the space.

In the apparel industry, cut pile fabric, with its soft touch and elegant sheen, is used in coats, dresses, trousers, and evening gowns, showcasing a blend of luxury and comfort. Automotive interiors and airline seats are also increasingly using this material to enhance tactile comfort and a sense of luxury.

In the decoration of public places such as hotels and theaters, cut pile fabric, with its excellent sound insulation and heat insulation properties, has become an ideal choice for interior design. With the increasing popularity of environmental protection concepts, more and more manufacturers are adopting recycled fibers or sustainable processes, driving the development of cut pile fabric towards green, environmentally friendly, and high-performance directions.

Cut pile fabric, with its soft feel, elegant texture, and diverse visual appeal, is becoming an indispensable high-quality fabric in modern life. Whether in home spaces or the fashion world, cut pile fabrics embody the perfect fusion of textile art and craftsmanship innovation with understated luxury and ultimate comfort. As technology continues to advance and consumer aesthetics evolve, cut pile fabrics will continue to demonstrate their unique market value and development potential through higher quality and wider applications.

English

English 中文简体

中文简体 русский

русский عربى

عربى