Among the vast array of textile fabrics, cut pile, with its unique surface texture and rich visual depth, has garnered significant attention in recent years. It's not a single fabric type, but rather a general term for a group of fabrics created through a specialized processing technique. Its core characteristic lies in its dense, soft, and uniform distribution of pile. These piles are precisely cut and uniformly arranged, preserving the warmth of the pile while imparting a structured appearance. Cut pile fabrics hold a prominent place in home furnishings, apparel, and decorative applications.

The Unique Structure and Craftsmanship of Cut Pile Fabrics

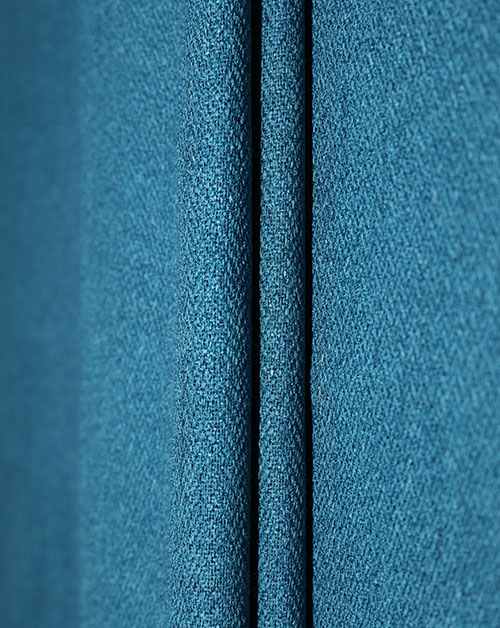

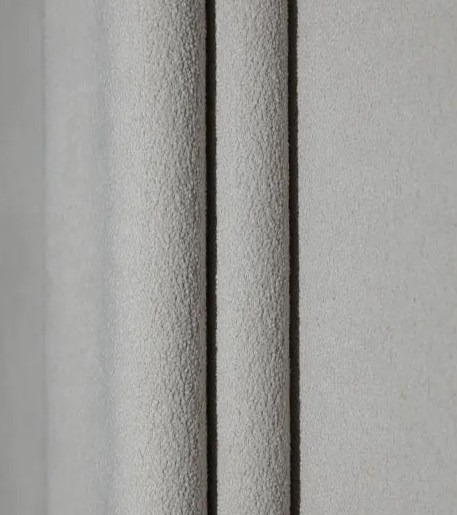

The appeal of cut pile fabric stems primarily from its ingenious structural design. Unlike ordinary fabrics, its surface is not a smooth, interwoven surface of yarns, but rather a patchwork of uniformly woven piles. These piles, like countless tiny fiber bundles, stand vertically or slightly tilted from the base fabric, forming a dense, "pile" surface. This structure not only provides the fabric with exceptional warmth and softness, but also creates a soft, shimmering effect when exposed to light, avoiding the harsh reflections common in ordinary fabrics and adding a sense of luxury.

This unique structure is the result of a complex production process. The cut pile process is typically performed after weaving is complete. The core step involves cutting the loops or piles on the fabric surface using specialized cutters. Before cutting, the fabric undergoes strict tension control to ensure uniform pile length. During the cutting process, the cutter's sharpness and speed are precisely controlled to prevent burrs or breakage. After cutting, the fabric undergoes subsequent processing, such as combing and brushing, to smoothen and even the pile, remove excess fiber impurities, and ensure a clean surface.

The cut pile process is not a one-time process; it requires close coordination with the weaving process. The fabric's base fabric structure directly influences the resulting cut pile effect. For example, a plain weave fabric produces a more evenly distributed pile after cut pile, while a twill weave fabric may exhibit subtle variations in texture, adding a unique texture to the fabric. Furthermore, different fiber materials exhibit significantly different performance in the cut pile process, providing ample room for the diversified development of cut pile fabrics.

Diverse Raw Materials Offer Rich Properties

The characteristics of cut pile fabrics are largely determined by the raw materials used. The addition of different fibers allows these fabrics to exhibit a wide variety of styles. Natural fibers are a common choice for cut pile fabrics. The addition of cotton fibers imparts excellent breathability and moisture absorption, creating a soft, skin-friendly feel, making them ideal for intimate apparel or home furnishings. Wool fibers provide excellent warmth and elasticity, resulting in a rich, thick pile surface, making them an ideal winter fabric.

Chemical fibers also play a key role in cut pile fabrics. Polyester fibers offer high strength and abrasion resistance, making cut pile fabrics not only washable and durable, but also maintaining a crisp, non-flopping pile. Nylon fibers are known for their excellent elasticity. Cut pile fabrics incorporating nylon fibers have a smooth feel and excellent stretch recovery, making them suitable for clothing that requires frequent movement.

With the advancement of textile technology, blending multiple fibers has become a new trend in cut pile fabrics. By strategically combining different fibers, the advantages of each raw material can be combined to offset the shortcomings of a single fiber. For example, a cotton-polyester blend of cut pile fabric retains the comfort and breathability of cotton while incorporating the wear resistance and durability of polyester, significantly enhancing the fabric's practical performance. A wool-nylon blend, on the other hand, offers improved elasticity and wrinkle resistance while maintaining warmth.

Wide Applications and Styles

Cut pile fabrics, with their diverse properties, are widely used in various fields, creating unique styles tailored to each occasion. In the home, cut pile fabrics are a powerful tool for creating a comfortable and cozy environment. Cut pile carpets have a soft, thick pile that feels comfortable underfoot and effectively absorbs noise, adding a sense of tranquility to the home. Cut pile curtains, with their rich texture and excellent light-blocking properties, provide privacy while creating a warm and gentle atmosphere. In the decorative world, cut pile fabrics have become a favorite among designers for their unique visual appeal. Cut pile sofa fabrics can enhance the look of a luxurious sofa and elevate the overall living room. Cut pile cushions can add a touch of color to a sofa or bed, their rich colors and textures blend seamlessly with the surroundings, creating a harmonious and unified decorative effect. Cut pile fabrics are even used in high-end venues to create unique wall textures, injecting an artistic touch into the space.

Maintaining and Identifying Cut Pile Fabrics

Although cut pile fabrics offer a premium feel, they require meticulous daily care to maintain their optimal condition. Because their dense surface easily attracts dust and debris, avoid using harsh cleaning tools during daily cleaning to prevent damage to the pile. For washable cut pile fabrics, it's recommended to use a neutral detergent, use a gentle wash cycle, and avoid rubbing or wringing to prevent the pile from falling apart or collapsing. When drying, choose a cool, well-ventilated area, out of direct sunlight, to prevent fading and hardening of the pile.

There are certain techniques for identifying high-quality cut pile fabric. First, observe the evenness of the pile. High-quality fabrics have piles of uniform length and are evenly distributed, with no noticeable sparseness or tangles. Second, feel the touch. Good cut pile fabrics feel soft and smooth, without any roughness or prickles. Third, check the bond between the base fabric and the pile. Gently pull the pile; if it doesn't fall off easily, it indicates a strong bond and good quality. You can also observe the fabric's color. High-quality cut pile fabrics have a uniform, natural color, free of noticeable color variations and stains.

Cut pile fabrics, with their unique texture and rich expressiveness, hold an irreplaceable position in the textile industry. From raw material selection to process innovation, from home decor to clothing, to daily maintenance and identification, they are constantly exploring new possibilities. With the deepening of environmental awareness and continuous technological advancement, we believe that cut pile fabrics will continue to bring more warmth and beauty to people's lives with their unique charm.

English

English 中文简体

中文简体 русский

русский عربى

عربى