In the modern textile industry, there are endless types of fabrics and processes. Among them, Brushing Fabric has attracted people's attention for its unique texture and wide application. Brushing fabric is not only popular because of its soft and comfortable touch, but also because of its multiple functional advantages, it has become the preferred material for many clothing brands.

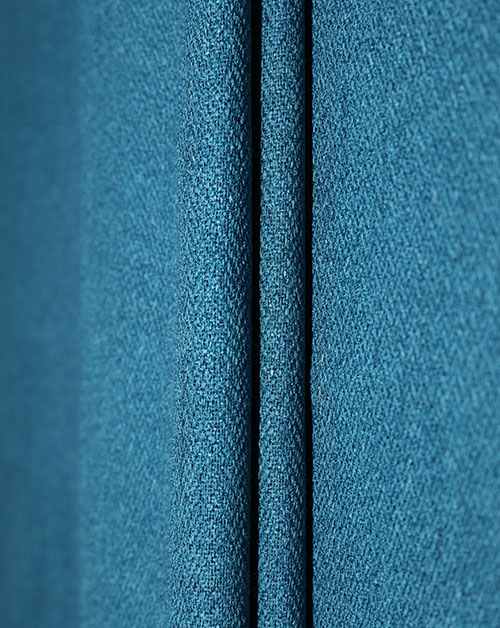

Brushing Fabric refers to textiles that have been specially treated to form a layer of fine plush on the surface of the fabric. Its production process usually includes brushing, shearing and other links. After the basic weaving of the fabric is completed, the fiber surface will be mechanically treated by a process called "brushing" using a special brushing machine. This treatment can produce a layer of fine short fibers on the surface of the fabric, forming a fluff-like effect. By brushing, the fabric feels softer and has a certain warmth retention.

In addition to the traditional brushing process, modern textile technology can also further process brushed fabrics according to different needs. For example, by using different types of fibers or controlling the brushing effect of the fabric to different degrees, the comfort, softness and elasticity of the fabric can be further improved. These changes have given brushed fabrics a variety of choices in many fields.

The most notable feature of brushing fabric is its soft touch. After brushing, the surface of the fabric becomes delicate and elastic, giving people a warm feeling like touching fluff. This touch makes brushed fabrics particularly popular when making autumn and winter clothing, providing a more comfortable wearing experience than ordinary fabrics.

Because the surface of brushing fabric forms a fluffy plush structure, this structure not only improves the softness of the fabric, but also enhances the warmth of the fabric. Plush can effectively capture air and form an air layer, thereby effectively isolating the cold outside and maintaining body temperature. Especially in cold seasons, brushed fabrics are often used to make thick coats, scarves and other warm clothing to meet people's dual needs for comfort and warmth.

Although the surface of brushed fabrics looks thick, its structure still has good breathability and moisture absorption. The gaps between the fibers of the brushed fabric allow air to circulate, avoiding the feeling of stuffiness when wearing. At the same time, this structure can effectively absorb sweat and keep the skin dry. Therefore, brushed fabrics are not only suitable for cold seasons, but also can be used in warm climates, especially when they need to be worn for a long time, so that comfort is guaranteed.

The durability of brushing fabric is also a major advantage. Due to the special brushing treatment, the fiber structure is more compact and stable, which makes it show strong wear resistance and wrinkle resistance in daily use. Whether after washing or during wearing, the shape of the brushed fabric can be better maintained and is not easy to deform or wrinkle.

The surface of brushing fabric often presents a subtle gloss, which is neither too smooth visually, but also has a natural three-dimensional sense. This appearance effect makes brushed fabrics widely used in the fashion field. For example, brushed wool fabrics are often used to make suit jackets or coats, giving the clothes a unique and elegant temperament.

The characteristics of brushing fabrics enable them to find suitable applications in many fields. From everyday clothing production to high-end textile processing, brushed fabric has become one of the most widely demanded materials due to its excellent comfort and functionality.

English

English 中文简体

中文简体 русский

русский عربى

عربى