With the continuous development of the textile industry, the types and functions of fabrics are becoming increasingly diverse. Among them, Brushing Fabric, as an innovative fabric, has received widespread attention and application due to its unique comfort and appearance.

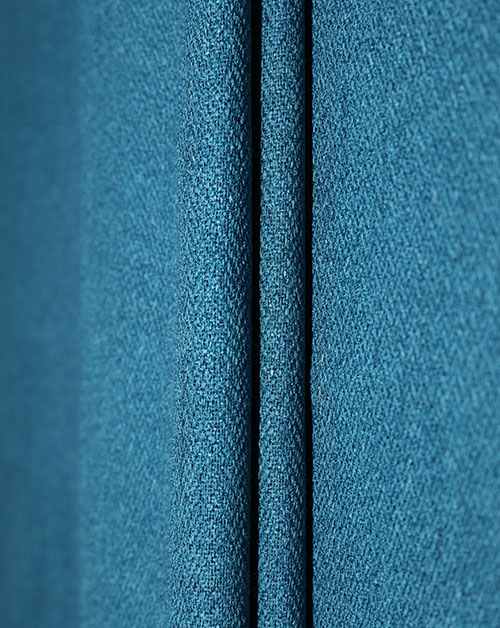

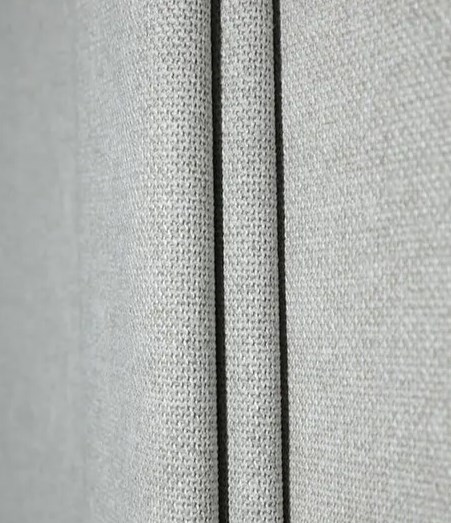

Brushing Fabric is a specially treated fabric with a layer of fine fluff formed on its surface by physical methods. It is soft to the touch and has high warmth retention and comfort. Common brushed fabrics include brushed cotton, brushed wool, brushed polyester, etc., which are particularly popular in autumn and winter due to their efficient thermal insulation and comfort.

The uniqueness of this fabric lies in the treatment process of the fluff on its surface, which makes it more fluffy and increases the thickness and elasticity of the fabric. At the same time, the fluff layer of Brushing Fabric can effectively capture air, thereby improving the thermal insulation effect of the fabric, making it an ideal choice for wearing in cold seasons.

The production process of Brushing Fabric

The production process of Brushing Fabric mainly treats the fiber surface by mechanical methods to produce tiny fluff on the fiber surface. Common production processes include brushing, sanding, grinding, etc. The specific process is as follows:

Fabric preparation: The fabric needs to be dyed and finished to achieve certain basic characteristics, such as softness, durability and color brightness.

Brushing process: The fabric passes through the brushing machine, and the surface fibers are stretched and twisted to form small fluffs. These fluffs are combined with the fibers to make the surface of the fabric form a delicate and soft feeling. This process is usually used for synthetic fiber fabrics such as cotton and polyester.

Drying and shaping: The brushed fabric needs to be dried at high temperature to ensure that the fluff layer is not damaged and restore the fabric to its softness and elasticity.

Post-processing: In order to improve the comfort, wear resistance and appearance of the fabric, the fabric will also undergo special post-processing processes such as shaping and softening.

Market application of brushing fabric

Brushing fabric is widely used in a variety of clothing due to its excellent comfort and warmth. Especially in cold seasons, brushed fabric has become the first choice of many consumers.

Autumn and winter clothing: Brushed fabric is usually used to make winter coats, thermal underwear, sweaters, scarves and other clothing. Its superior warmth retention makes it an indispensable choice in cold climates.

Home Textile Products: Brushed fabrics are also widely used in the home textile field, and are commonly seen in products such as bed sheets, quilt covers, curtains, etc. Due to its comfort and touch, home textile products made of brushed fabrics are gradually gaining popularity in the market.

Sportswear: With the popularity of sports fashion, brushed fabrics are gradually entering the sportswear market. Brushed fabrics are often seen in sports suits, sweatpants, and jackets, and their comfort and elasticity make exercise more comfortable.

Children's clothing: The soft touch of brushed fabrics is particularly suitable for children's clothing, especially winter coats, sweaters and other items. It not only provides sufficient warmth retention, but also avoids irritation to children's skin.

Advantages of Brushing Fabric

Comfort: The surface of Brushing Fabric is delicate and soft, and it is very comfortable to wear. The design of the fluff makes the contact between the fabric and the skin more intimate, which can bring a better touch experience.

Strong warmth retention: Brushing Fabric can effectively isolate the air and provide better insulation due to the presence of fluff. In cold weather, wearing clothes made of brushed fabric can effectively resist the effects of low temperatures.

Good moisture absorption and breathability: Brushing Fabric has good moisture absorption and can absorb sweat discharged from the body while maintaining breathability, avoiding moisture accumulation and keeping the skin dry.

Durability: Fabrics treated with brushed fabric generally have strong wear resistance. Even after multiple wearing and washing, the fluff layer of the fabric is not easy to fall off, ensuring the long-term use of the fabric.

Brushing Fabric has been widely used in many fields due to its excellent comfort and warmth retention. With the continuous innovation of textile technology, the functionality, environmental protection and fashion of brushed fabric will continue to improve. In the future, brushed fabric will occupy an important position in more clothing and household items, bringing consumers more comfortable, warm and fashionable choices.

English

English 中文简体

中文简体 русский

русский عربى

عربى